DDA Wall Mounted Handrail

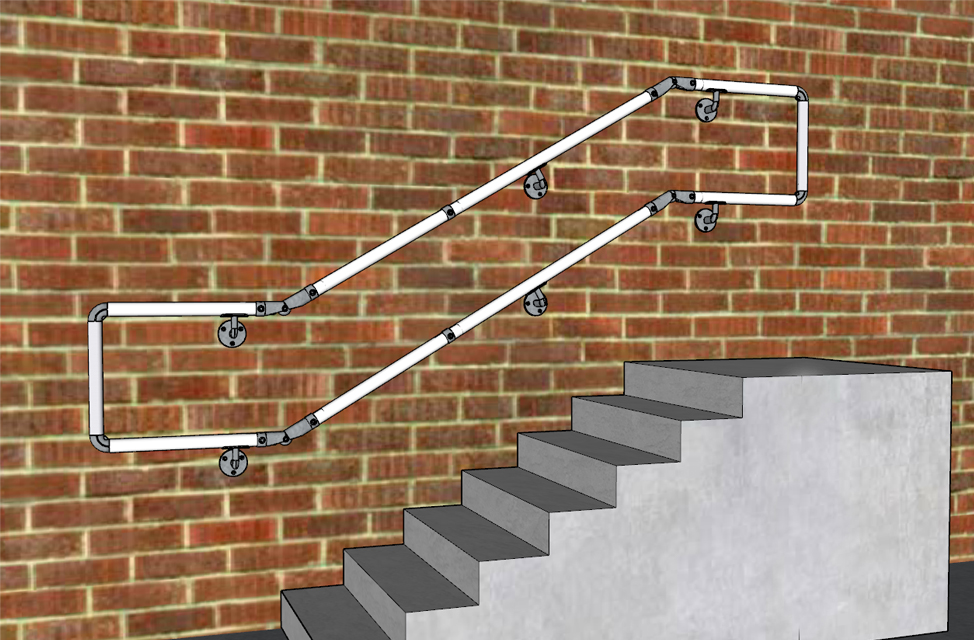

Not only does our Alvin Key Clamp DDA Compliant Handrail Range give our customers the ability to install their system fixed to the ground or using baseplates, but there is also the option to fix a handrail to the side of a building. Using our simple easy-to-assemble fittings, you will be able to achieve a compliant handrail in no time.

If this particular system does not meet your specific requirements/design however, the beauty of our DDA Range is our fittings can be configured to make any guardrail system you wish. You can find all our DDA How To Guides here. If you need further assistance or have any sketches you wish for us to look over and advise, please contact us on 020 8254 2626 or email sales@alvinkeyclamp.co.uk

Decide if you just need a single top-rail or if a mid-rail is required. Part M of the building regulations does not mandate having a mid-rail. On open sided ramps, landings or stairs the case is clear because the mid rail also acts as a barrier preventing wheelchair wheels from slipping off the edge underneath the top rail. Where the access route is enclosed by a wall, it is a case of assessing the likely users of the site to decide if a mid-rail will be of benefit. One other factor is that Part M requires that handrails be continuous across ramps/stairs and landings, so if you already have a mid-rail on other parts of your access routes, it is wise to continue it across all the routes on your site to provide consistency.

For a single rail our D005 clamp provides a smooth return to the wall, fulfilling the requirement of Part M to minimise the risk of clothing being caught. It attaches to the tube using an A09 clamp and two D797 sealing rings.

Self-tapping screws are needed to attach the tubes underneath the D746. The A08's will be needed to connect the tubes, with a pair of D797 sealing rings either side.

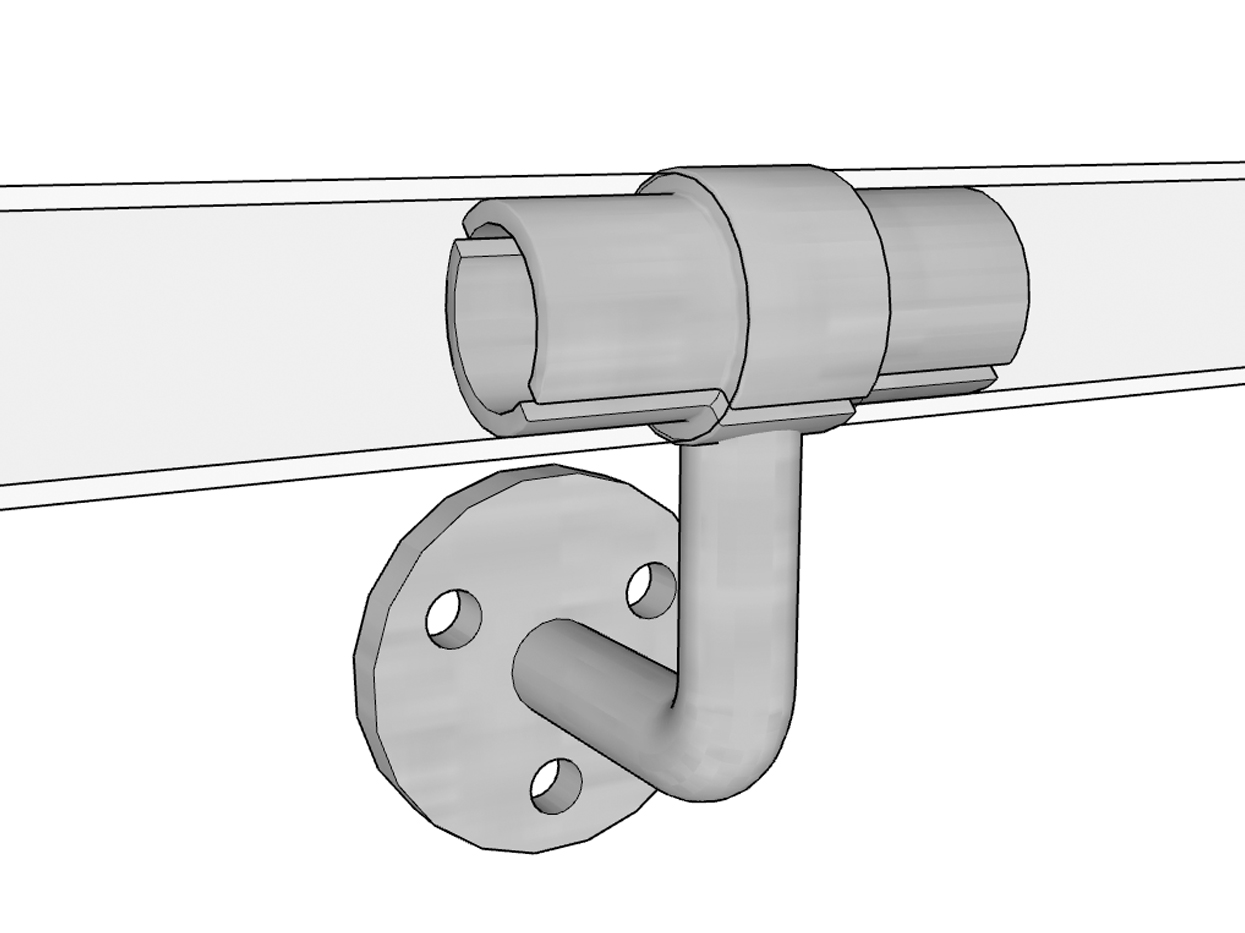

The rail continues parallel to the wall, using D746 wall clamps. The strength of your wall will impact how often you need to place these clamps but most customers find every 1100mm to be sufficient.

For a double rail (ie. Top and mid-rails), you can either build two identical rails terminated as above, or you can use an end loop kit to smoothly join the two rails together.

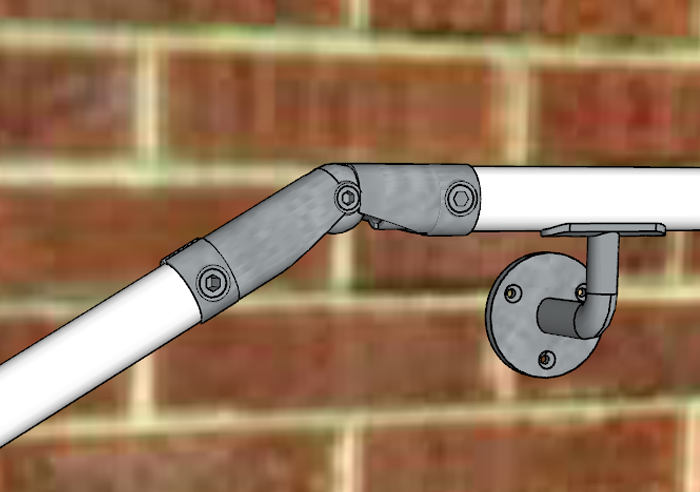

Gradient changes can be incorporated in the same way as an upright mounted handrail. The gradient change needs to be within 500mm of a wall fixing. The D009 gradient change clamp requires two A09 inline joiners and four D797 sealing rings.

Additionally, as pictured below, you can save on internal joiners if you can site your gradient change immediately next to a wall mounting position, with one end of the D009 attaching directly to the wall mount clamp itself.

The rail is usually terminated back to the wall again using another D005 + A09-7 combination. Remember that the handrail needs to extend at least 300mm beyond the top and bottom of the ramp or stairs.

To meet Part K or Part M of the building regulations, handrail should "not become excessively cold or hot to touch" and you should “ensure that the handrail will contrast visually with the background against which it is seen without being highly reflective”. This can be achieved through either Powder Coating or painting the handrail. Very dark colours may get hotter in the summer sun. Find out more information on our Powder Coating service Powder Coating service here.

Expanding DDA Handrail Alternative

Follow the previous steps, although with the D745, the tubes will slot in either side and tighten the grub screws with an allen key.

Discuss your enquiry

Share site photos

Send us plans/drawings

Telephone

London: +44(0)20 8254 2626

Sheffield: +44(0)114 312 2250