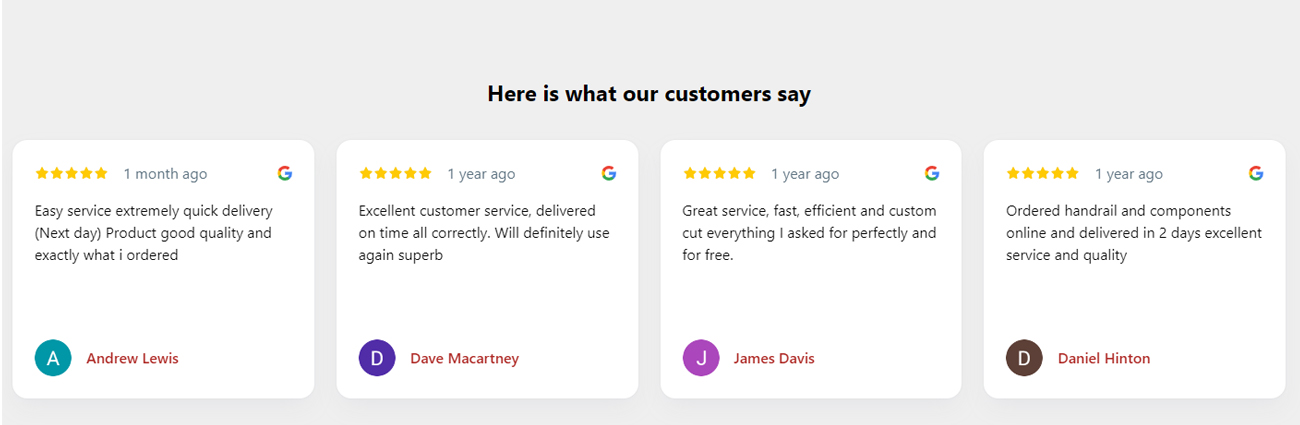

Main Image

How To Install Your DDA Uprights

Fixing your uprights to the ground or wall correctly is crucial to maintaining the overall strength of the system. Handrails must provide firm, dependable support to anyone who needs it and they should not wobble under load.

All products mentioned in the following blog can be found and purchsed at the bottom of the page.

If you need further assistance or have any sketches you wish for us to look over and advise, please contact us on 020 8254 2626 or email sales@AlvinKeyClamp.co.uk

Main Image

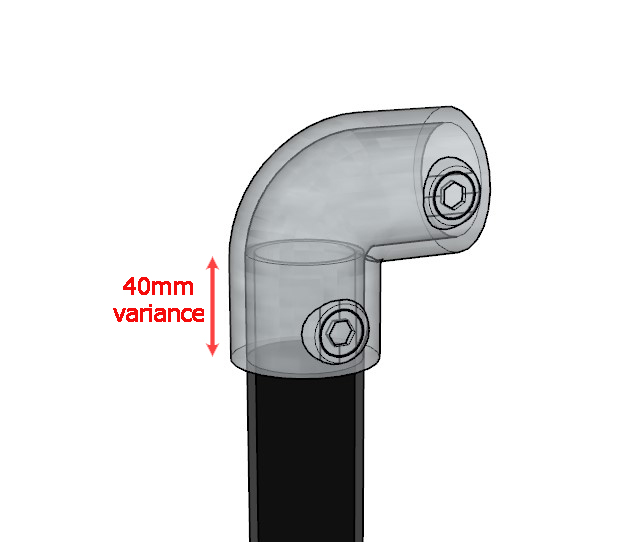

In this example we are assuming you need a 1000mm high handrail and are fixing your uprights directly to the walking surface, not to the side of the ramp or to a parapet wall (which we will cover later). If you do need to fix your handrail to a wall or the side of a ramp, use either our A14 and A15 side fixing baseplates. Using our DDA clamps, your top rail will sit between 80mm and 120mm higher than the top of the upright. This variance comes from how much you push the upright into the A06 clamp at the top and is useful for fine adjustments during construction.

We shall start with our posts fixed using A12 Baseplates, these are for flat areas or slight gradients up to 3º, for gradients of 4-10º use our G12 baseplates. Both baseplates add 10mm to the height of the upright tube. Cut tubes down to roughly 900mm each and secure inside the baseplate using the grub screws. All grub screws should be tightened to a torque of 39Nm. The A12 or G12 baseplates must be oriented with the fixing bolt holes either side of the upright, at 90º to the run of handrail. Failure to follow this step could lead to your handrail becoming wobbly over time.

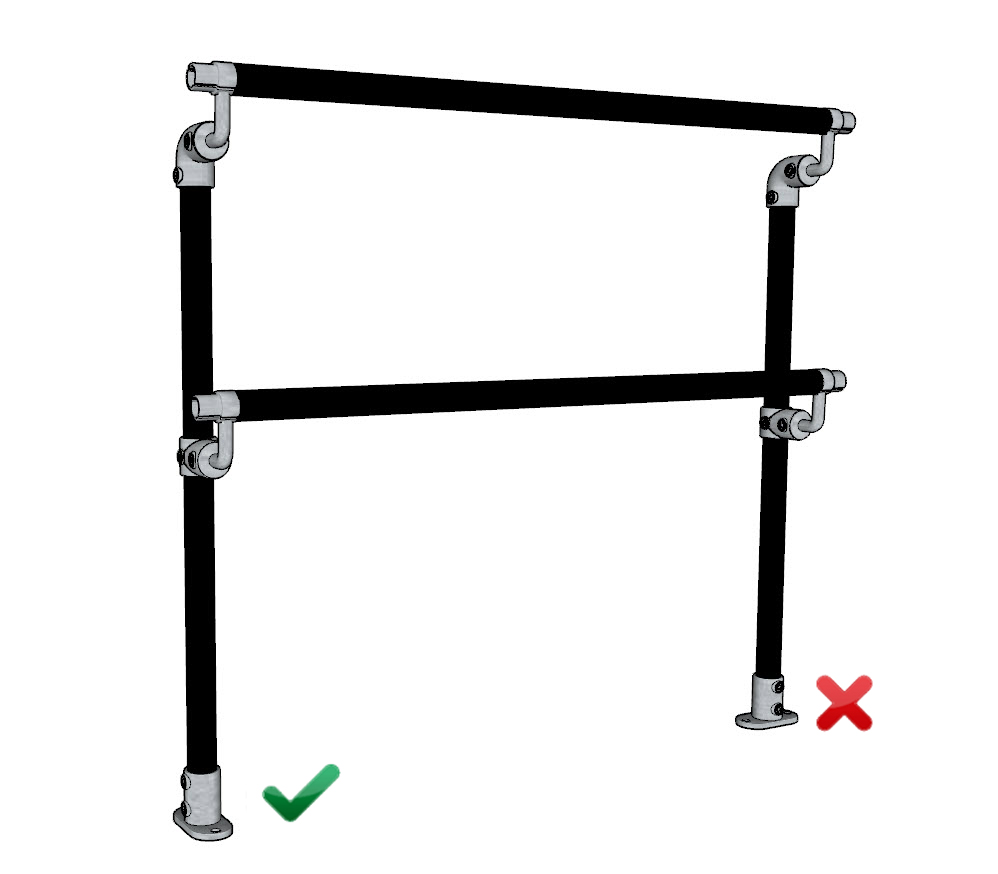

If you are fixing your uprights into the ground, your cut tube will need to be a little longer to have enough tube underneath the ground, as well as having the necessary height from ground level to the top of the upright.

Place the A02 & A06 clamps on first at the designed height. Normally the A02 will be roughly halfway down the tube so there is 600mm from the ground surface to the top of the mid-rail (Image A).

Slot the D747 clamps inside the exposed clamps and then tighten the grub screws with an Allen Key (Image B).

Main Image

The D797 sealing rings will go either side of the D747's (Image C) before the tube is inserted (Image D). Finally, tighten the grub screw of the D747's to 39Nm torque so the tube is held securely.

Main Image

With the first upright in place,you are now ready to repeat the process again for the next upright. Remember that you need an upright within 500mm of any corner or gradient change, other than that you just need to evenly space your uprights according to your required maximum spacing.

All components (excluding the A12 and G12 baseplates) can be purchsed in the below Kit.

Telephone

London: +44(0)20 8254 2626

Sheffield: +44(0)114 312 2250

WhatsApp Text/ Picture Message

Number: 020 8254 2626

Scan the QR Code to start a WhatsApp chat with us