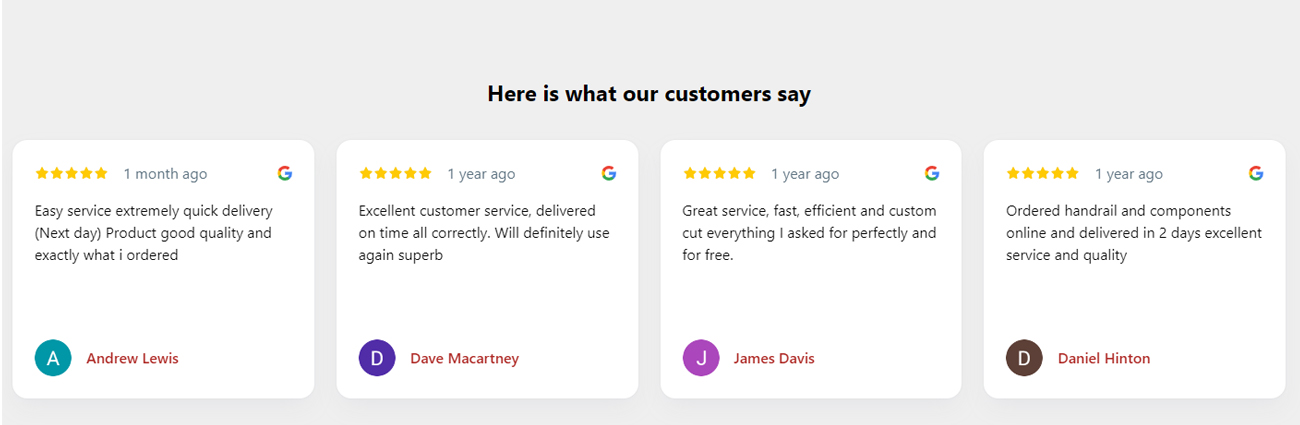

Main Image

How To Set Your DDA Compliant Uprights On Brick

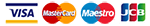

Fixing any handrail to a brick topped or full brick wall requires special consideration to ensure that the fixing points can tolerate the forces applied over time. Below we discuss two possible options for achieving a solid fixing to a brick wall.

Our Alvin DDA Handrail Range allows fittings to be configured to make any disabled access handrail system you wish. If you need further assistance or have any sketches you wish for us to look over and advise, please contact us on 020 8254 2626 or email sales@alvinkeyclamp.co.uk

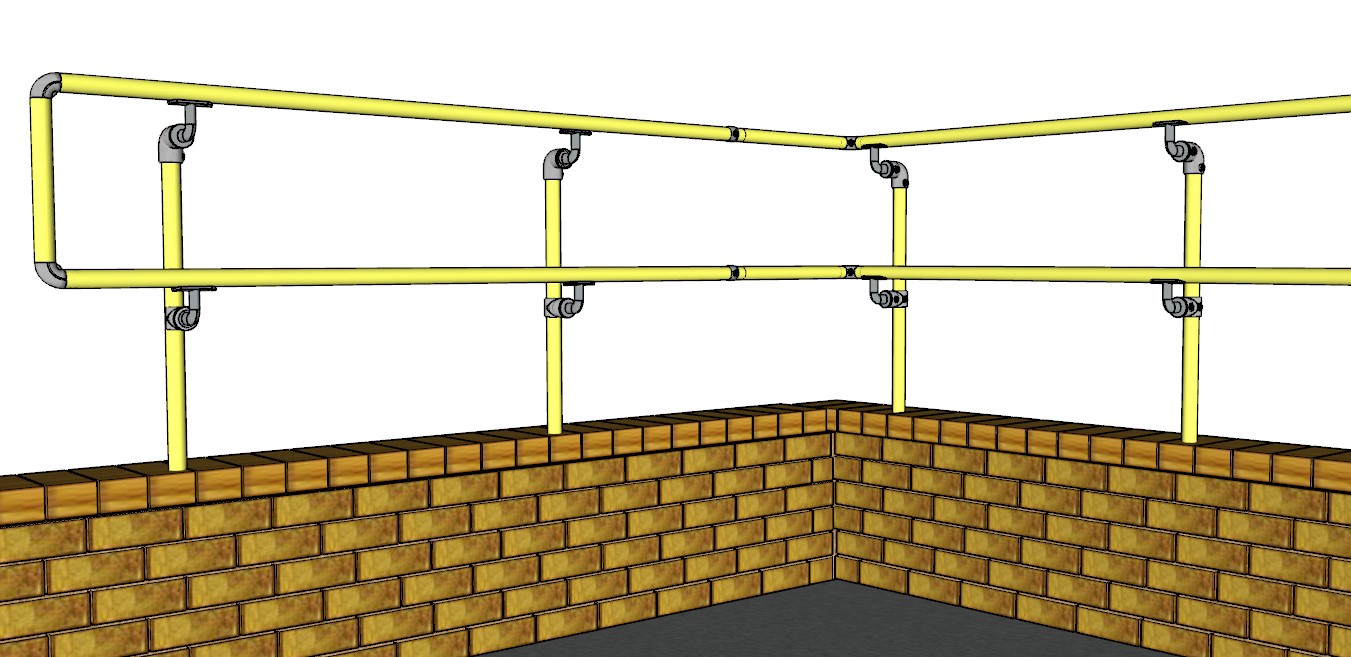

While our A12 baseplates can be used for uprights on concrete up to 4 deg, and our G12's on ramps of 4-11 deg, it is not recommended to use them directly on top of brickwork or paving slabs without additional thought about the fixing type. If the handrail is put under excessive pressure over time, this can cause the top layer of bricks to either break off, or fracture, causing the handrail to lean to one side over time. This can significantly affect the strength and stability of the handrail, posing a risk to users, and would also require more work, time and money to replace or fix.

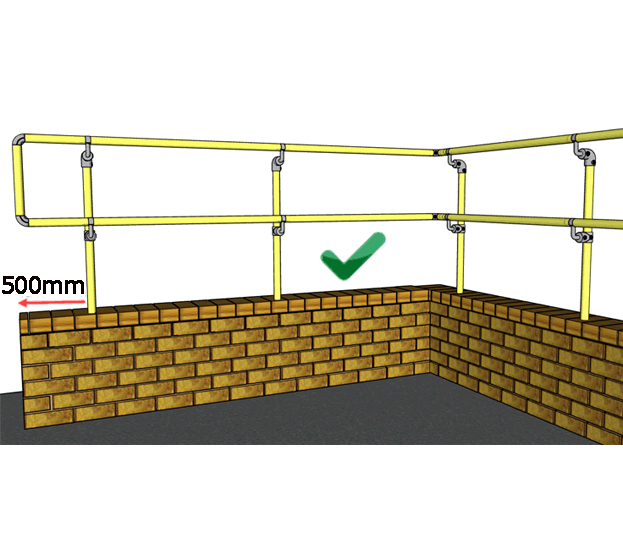

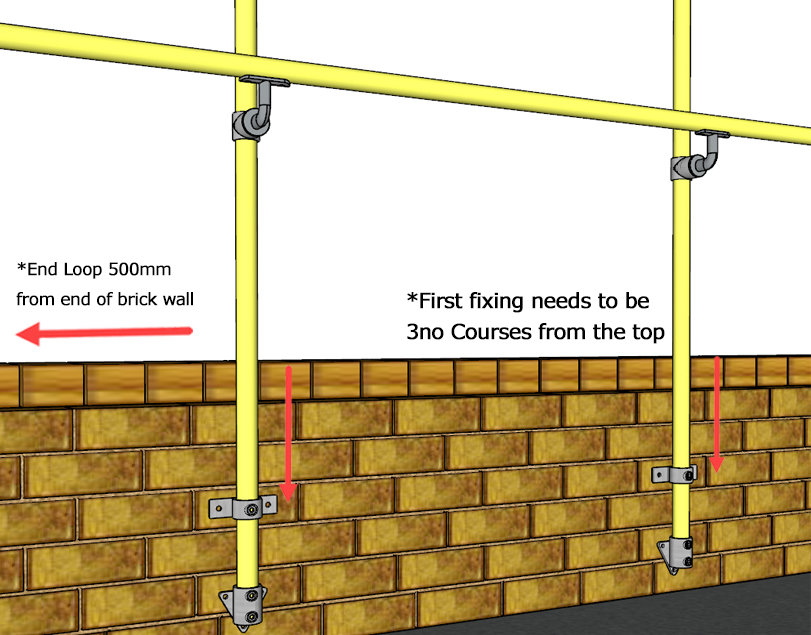

If you cannot core drill into the brickwork, or if there is not enough room on top, another option is to fix your uprights to the side of the brickwork. Clamps to consider for this would be our A15/A35 clamps to get the upright to sit as close to the wall as possible. Ensure the first fixing starts from a minimum of three courses down from the top of the brickwork. Alternatively, if the brick/slabs have a lip that protrudes out at the top, consider the A14/A34 clamps to sit the upright a little further from the wall. Please contact us for exact measurements. Generally chemical anchor type fixings are preferable to expansive bolts because they do not apply additional sideways load on the fixing hole.

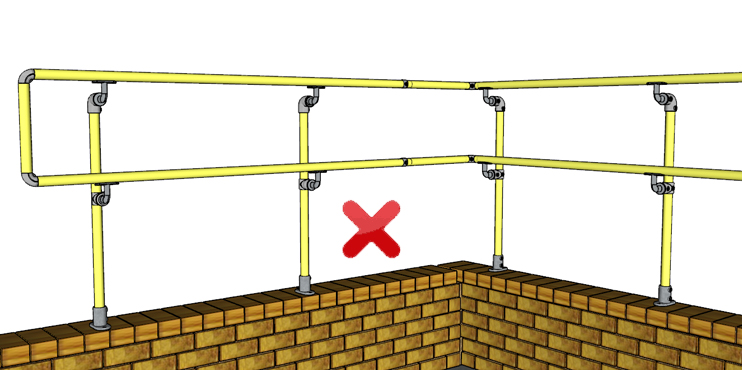

As a last resort, if you must use baseplates on top of a brick wall, you should use long sections of M12 threaded rod and drill down through at least three brick courses, using chemical anchor resin to secure the threaded rod in place.

In any case it is essential to ensure the surface you are attaching your handrail to is strong enough to take the design loads of the handrail.

To meet Part K or Part M of the building regulations, handrail should "not become excessively cold or hot to touch" and you should “ensure that the handrail will contrast visually with the background against which it is seen without being highly reflective”. This can be achieved through either Powder Coating or painting the handrail. Very dark colours may get hotter in the summer sun. Find out more information on our Powder Coating service here. Also ensure the handrail finishes with an End Loop Kit.

As well as the fixing method, the spacing of your uprights is critical to building a sturdy and compliant handrail. You can read our blog about how to calculate upright spacing calculate upright spacing here.

Other Recommended DDA Blog Pages

Telephone

London: +44(0)20 8254 2626

Sheffield: +44(0)114 312 2250

WhatsApp Text/ Picture Message

Number: 020 8254 2626

Scan the QR Code to start a WhatsApp chat with us