Main Image

How to Assemble Your DDA Compliant Double Handrail

According to Part M of the Building Regulations, access routes should not be wider than 1.8m without being divided using a handrail. Luckily, our DDA handrail system can easily accommodate this requirement. We have detailed a simple example below.

If this particular system does not meet your specific requirements/design however, the beauty of our DDA Range is our fittings can be configured to make any guardrail system you wish. If you need further assistance or have any sketches you wish for us to look over and advise, please contact us on 020 8254 2626 or email sales@AlvinKeyClamp.co.uk

Main Image

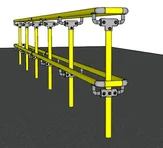

For each of the uprights, you will need to use clamps from our standard Alvin Key Clamp range. Place the upright tube (900-1000mm) inside the A12 Baseplate. The A22 clamp follows suit tightened in the middle of the clamp. At the top of the upright tube, attach an A04.

Main Image

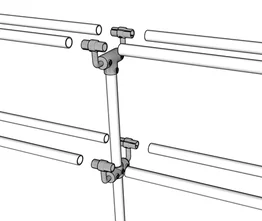

Either side of both of the A04 and A22 clamps, insert pairs of D748 clamps.

D748's help you to run the handrails in longer lengths of tube, to reduce the amount of tube cuts required for example. Fixed using a pop riveter or self-drilling screws, these clamps can be a practical solution for longer runs of handrail.

Uprights are generally placed roughly 1100mm apart.

Main Image

The flexibility of the Alvin DDA system means that we can use this single upright approach even where there is a gradient change between the two walkways or ramps. As the height of the rails either side of the uprights diverges, we can support each side separately from the same upright, using the standard A02 and D748 combination at the required height up the upright.

Place A09 sleeve joiners to the exposed tubing. Depending on the tube lengths you purchase, ensure you have enough sleeve joiners to complete your run.

Main Image

Now is the time to connect it all together. Depending on how far the last upright is to your desired length, the D725 clamps should be inserted in the exposed tube and turned so the other end is facing horizontally. A small peice of tube will be needed to connect the two D725 together, forming an end loop. Your handrail should now be complete.

Main Image

For the expanding version, instead of the D748's, replace these with the D747.

Place cut tubes on the exposed D747 clamps (customers generally go with 1093mm centres to minimise cutting waste) and repeat this process until you have reached the desired length you need the handrail to be.

Main Image

To meet Part K or Part M of the building regulations, handrail should "not become excessively cold or hot to touch" and you should “ensure that the handrail will contrast visually with the background against which it is seen without being highly reflective”. This can be achieved through either Powder Coating or painting the handrail. Very dark colours may get hotter in the summer sun. Find out more information on our Powder Coating service here.

If your DDA Handrail system has multiple variations within the system, such as gradient changes, you can also purchase these kits below:

Telephone

London: +44(0)20 8254 2626

Sheffield: +44(0)114 312 2250

WhatsApp Text/ Picture Message

Number: 020 8254 2626

Scan the QR Code to start a WhatsApp chat with us